& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

AECO

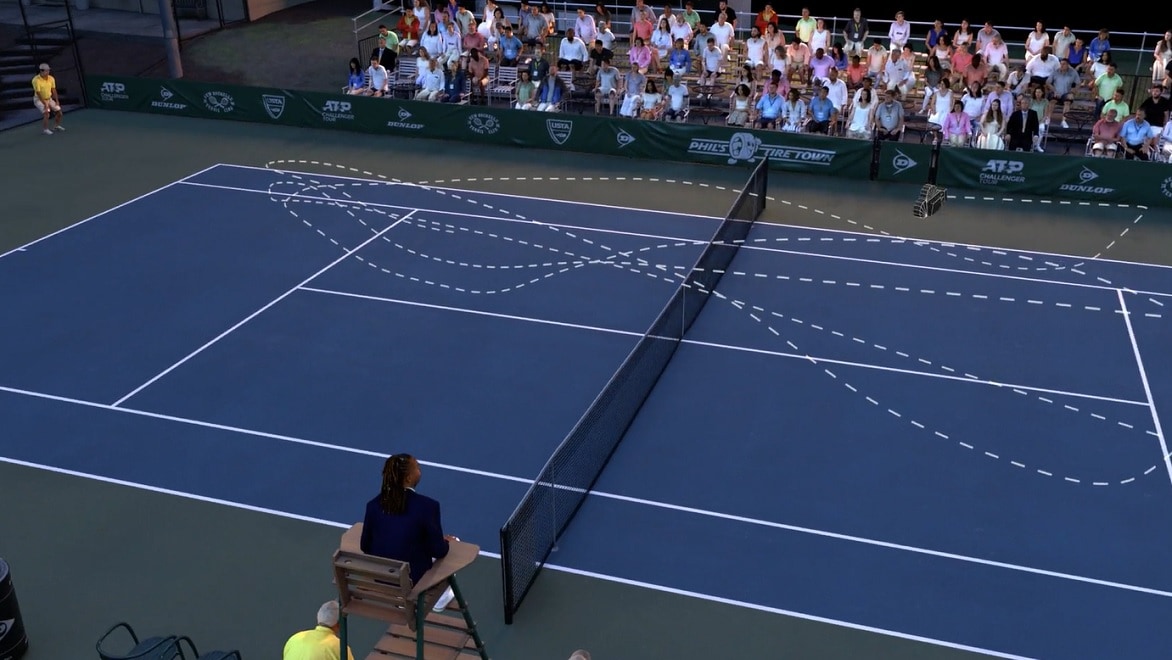

Global architecture firm Populous borrows concepts from industrialized construction and product manufacturing to build transformative, eco-friendly sports complexes—and deliver them faster, cheaper, and better.

AECO

An ancient ceramics factory has a new life as Taoxi Mingzhu, a modern mixed-use complex. Discover the challenges and innovations behind this architectural feat.

Emerging Tech

Designing Beijing’s new Sub Center Theater complex meant using smart construction technologies to perfect everything from architecture to acoustics.

“AutoCAD, Revit, and Civil 3D play a crucial role in the design and construction of sustainable buildings by enabling designers to optimize building performance, select environmentally friendly materials, manage resources efficiently, and collaborate effectively.”

— Noella Nibakuze, Design Director, MASS Design Group

PD&M

At Kia Global Design, generative AI is helping automotive designers ideate and innovate faster, accelerating the process of taking a design from initial concept to final form.

PD&M

Cosmic Robotics, an Autodesk Research Residency Program member, uses advanced robotics and cutting-edge hardware and software to develop robots that can take on the labor-intensive task of solar farm construction.

PD&M

With a unified cloud platform for collaboration among product designers, Native Instruments provides musicians with the hardware and software to find the perfect sounds.

“Without [AutoCAD Electrical], we would not be able to build, test, and run the equipment that we use as part of our atmospheric carbon dioxide capture process.”

— Max Scholten, Head of Commercialization, Heirloom

M&E

For its recent game New Tales from the Borderlands, an automated pipeline helped Gearbox create 4x more cinematic gameplay in half the time–and enabled artists to spend 50% more time on creative work instead of logistics.

M&E

Find out how visual-effects company Wētā FX has driven performance-capture methods to new levels of realism in blockbuster franchises such as The Lord of the Rings, Planet of the Apes, and Avatar.

Emerging Tech

Disney innovation elevates storytelling and the creation of immersive experiences—processes that, in its theme parks, require extensive BIM coordination.

“Artists know how to use Maya and it’s stable. We can build our pipeline, lighting tool sets, and other processes around it and know we’ll create a reliable output. It’s battle-tested for sure, and integrates nicely with Flow Production Tracking.”

— Brian Drewes, VFX Supervisor and Founder, Zero VFX

Learn how people in a wide array of industries are using Autodesk products and solutions.

Meet the innovators who are transforming architecture, engineering, construction, product design, manufacturing, media, and entertainment.